Article by Chris Mader, codes and approvals support engineer, OMG Roofing Products

At last count, an estimated 4.5 GW of solar PV was in operation at commercial locations across the country, and much of it was roof mounted. While commercial roofs are appealing for many reasons, rooftop installations frequently create unforeseen challenges for the roofing system and potential problems for the building owner. It is therefore critically important for all parties involved, including engineers and installers, to fully understand commercial roofing systems, including their composition, in order to limit exposure and liability.

The first step is to understand how commercial roofs are built. While it may seem obvious, it’s important to recognize that the primary purpose of the roofing system is to protect the building asset by keeping water out. Roof system warranties are issued by the OEM and are explicit in terms of liability—anything outside of a roof’s primary purpose is not covered. Therefore, some key issues to consider include:

![OMG-roofing-4]()

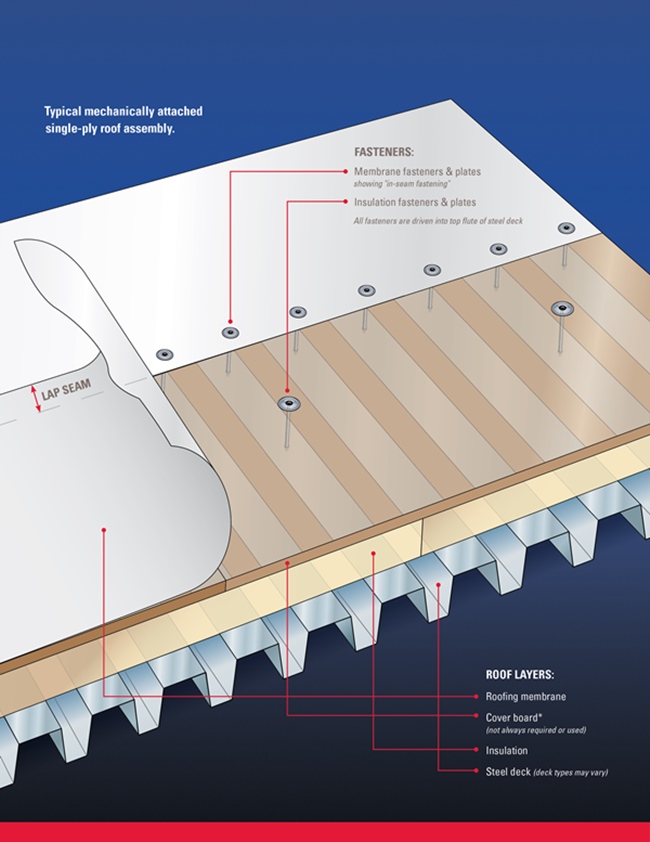

Figure 1: The anatomy of a mechanically fastened single-ply roof on a commercial building. (Photo: OMG Roofing Products)

How will the PV system affect the roofing system over the life of the array?

How will increased traffic from installation and maintenance traffic affect the roofing system?

How will the PV system affect the roofing system manufacturer’s warranty?

Just because the structure itself can handle a ballasted array for 20 years doesn’t necessarily mean the roof system can. It is generally understood that the roof system needs to last for the entire life cycle of the solar array, but it is easy to overlook seemingly small details that can have huge impacts over the 20-plus year service life of the array.

The Anatomy of a Commercial Roof

The majority of commercial roofing systems in North America are mechanically attached. Mechanically attached roofs are secured to the substrate—a term used in roofing to describe the structural roof deck—using screws and “plates,” or oversized washers designed for the application. It’s important for installers to know what makes up the roof deck. While the majority of new roof decks in North America are steel, there are a myriad of other deck options, including gypsum, concrete and wood. Different deck types may require a different approach for designing, installing or securing solar rack systems.

Typically, a layer of rigid insulation is installed directly on the substrate (see Figure 1). The most popular type of flat roof insulation in North America is polyisocyanurate (iso), but other insulation options include extruded and expanded polystyrene (XPS and EPS, respectively). High density cover boards made from gypsum or high density iso are also used in some cases. While each has its own advantages and disadvantages, especially as it pertains to managing the installation and life cycle of a solar array, high density cover boards are generally better able to handle the additional traffic and compressive loading of a PV system. Furthermore, they may be important to use on installations where additional ballast is necessary or high foot traffic from maintenance or other operations is expected.

The top layer is the waterproofing cover. The market today is predominately single-ply materials including white thermoplastics (PVC or TPO) and black rubber (EPDM). Other roofing materials still prevalent in the commercial market include asphaltic materials called built-up roofing (BUR) or modified bitumen (Mod Bit). Understanding which specific roof type is installed can help determine the best method of attachment for maintaining the integrity of the roofing system.

![Figure 2: Thermoplastic membrane seams are fused using a robotic hot-air welder to create a bond that can be stronger than the membrane itself. (Photo: Leister Technologies)]()

Figure 2: Thermoplastic membrane seams are fused using a robotic hot-air welder to create a bond that can be stronger than the membrane itself. (Photo: Leister Technologies)

White thermoplastic materials represent the highest percentage of commercial roofs installed. The material is typically provided in rolls 10-ft wide by 100-ft long. The membrane is rolled out onto the insulation, mechanically fastened along the edge or seam. The next roll overlaps the fasteners and the seam is fused using hot air (at least 900°F) to create a bond that can be stronger than the membrane itself (see Figure 2).

Today’s roof-mounted solar rack systems are largely designed around ballast as the primary method for holding the solar array in place. This is because many building owners and installers assume that not penetrating the roof system is beneficial. While it is true that a purely ballasted array will not penetrate the roof, it should be understood that over the past 20 years, the commercial roofing industry has moved away from the once prevalent method of ballasting roofs due to excessive dead load weight on the structure, as well as the impact that wind can have on such systems. Furthermore, many of today’s commercial buildings cannot structurally handle solar arrays secured entirely with ballast, as the amount of ballast required exceeds the structural capacity of the building. A value engineered building that meets code minimums will likely fall short when evaluated for a purely ballasted array. In these situations, using mechanical attachments may allow the contractor to reduce or eliminate ballast from the project.

The option to structurally secure solar arrays is a point of discussion throughout the industry. Building owners want to avoid having holes cut into their roof system because of leak concerns. However, some roof-mount products are designed specifically to avoid having to core the roof down to the structural deck. These new style mounts are secured to the structural roof deck in a manner that is consistent with how the roofing system was originally installed (see Figure 3). Securing these roof-mounts to the structural deck and heat welding them in place not only helps eliminate rack movement on the roof (even fully ballasted rack systems move around on the roof, likely impacting the life expectancy of the roofing material), but also remains watertight if catastrophic failure occurs, depending on the specific roof-mount used (Figure 4).

The alternative of simply welding a roof-mount to the waterproofing cover may not be the best long-term solution. Remember, the primary role of the waterproofing layer is to keep the building dry, and the roof system was not intended to resist the point loads introduced by these mounts.

Last, but not least, contractors must understand whether the roof in question is under warranty. Typically, building owners purchase a long-term warranty for their new roof. Such warranties usually include an “overburden” clause whereby installing things like solar rack systems without first notifying the roof system manufacturer will void the roofing warranty. It’s always a good idea to understand whether the roof is under warranty. If it is, you should determine the process for having the solar system included. Most roofing system manufacturers will work with you to ensure the roof remains under warranty.

Contractors installing solar PV on commercial buildings have a responsibility to understand not only how best to approach the project, but also how to avoid down-stream issues. Having a sound understanding of commercial roofing systems and practices will go a long way in helping to provide your customer with a system that will work for the long term.

![Figure 3: Some new style mounts are secured to the structural roof deck in a manner that is consistent with how the roofing system was originally installed, and can help to reduce or eliminate ballast.]()

Figure 3: Some new style mounts are secured to the structural roof deck in a manner that is consistent with how the roofing system was originally installed, and can help to reduce or eliminate ballast.

![Figure 4: Some mounts are designed to remain watertight even if a catastrophic failure occurs.]()

Figure 4: Some mounts are designed to remain watertight even if a catastrophic failure occurs.

Solar Power World

![]()

![]()

RV8H r

RV8H r

The problem is, if Joe Sunny doesn’t own the RECs for his system, he just landed that deal in direct violation of Federal Trade Commission rules. And if someone, perhaps his competitor or a website reader, complains to authorities, he could receive a warning letter in the mail. If he fails to change his “messaging,” legal consequences can follow from the FTC or the party that actually owns the RECs. From now on, according to the FTC, Joe Sunny will have to tell his potential customers, friends and family that he “provides the physical space for the production of clean to furrow brows.

The problem is, if Joe Sunny doesn’t own the RECs for his system, he just landed that deal in direct violation of Federal Trade Commission rules. And if someone, perhaps his competitor or a website reader, complains to authorities, he could receive a warning letter in the mail. If he fails to change his “messaging,” legal consequences can follow from the FTC or the party that actually owns the RECs. From now on, according to the FTC, Joe Sunny will have to tell his potential customers, friends and family that he “provides the physical space for the production of clean to furrow brows.

As the solar industry continues to mature, the expectations of PV systems grow.

As the solar industry continues to mature, the expectations of PV systems grow.

“Our old building was just too small,” said M.S. Huang, president of Delta Products Corp. The new facility – which is mostly office space – can handle up to 500 workers, though about 200 currently work there.

“Our old building was just too small,” said M.S. Huang, president of Delta Products Corp. The new facility – which is mostly office space – can handle up to 500 workers, though about 200 currently work there.

“With generous government incentives available, companies such as Command Access Technologies are finding that solar systems can be installed inexpensively and will dramatically reduce their monthly electricity bills,” said Alan H. Lee, CEO of ecoSolargy. Lee estimated that Command Access Technologies would save $25,000 in its first year, and increasing amounts in following years as electricity costs increased.

“With generous government incentives available, companies such as Command Access Technologies are finding that solar systems can be installed inexpensively and will dramatically reduce their monthly electricity bills,” said Alan H. Lee, CEO of ecoSolargy. Lee estimated that Command Access Technologies would save $25,000 in its first year, and increasing amounts in following years as electricity costs increased.

Ingeteam has supplied its PV inverters to the recently-inaugurated PV solar plant in Moquegua, located in southern Peru. This plant, which was recently inaugurated by the country’s President, Ollanta Humala, occupies a surface area of 134 hectares and represents an investment of more than 35 million euros.

Ingeteam has supplied its PV inverters to the recently-inaugurated PV solar plant in Moquegua, located in southern Peru. This plant, which was recently inaugurated by the country’s President, Ollanta Humala, occupies a surface area of 134 hectares and represents an investment of more than 35 million euros.

“We’re always looking for ways to better serve our constituents, so we’re quite pleased to have this project underway,” said Middletown Burgess (Mayor) John Miller. “The new system will deliver enough electricity to power 100% of the requirements of our water and wastewater facilities, lowering our electricity bills, and saving us a significant amount of money over the next 20 years. This will help the Town to manage its budgets more effectively for the future.”

“We’re always looking for ways to better serve our constituents, so we’re quite pleased to have this project underway,” said Middletown Burgess (Mayor) John Miller. “The new system will deliver enough electricity to power 100% of the requirements of our water and wastewater facilities, lowering our electricity bills, and saving us a significant amount of money over the next 20 years. This will help the Town to manage its budgets more effectively for the future.”